Many

pharmaceutical products are temperature-sensitive because of which great care

is practiced for their storage and shipping. This would mean that to preserve

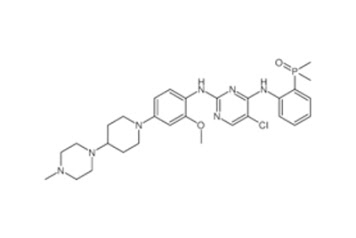

the integrity of these products like Brigatinib

Intermediate, setting the environment to a pre-defined temperature range is

necessary as the increase or decrease in the temperature would greatly

compromise their quality.

Take

for example to better understand why utmost care is required in handling

pharmaceuticals the nature of such products as vaccines and probiotics.

Vaccines and probiotics consist of actual living organisms and proteins and due

to this reason, they are among the most sensitive pharmaceutical products.

There can occur damage to these delicate products due to any type of fluctuations

in the temperature of the environment. Various technologies are employed in the

cold chain shipping industry because of the sensitive nature of these

pharmaceutical products that require a stable temperature.

Temperature

mapping is of great importance in the process when it concerns the storage and

shipment of pharmaceuticals. This needs to comply with the regulations ordered

by different controlling organizations. The process includes monitoring the

temperature along with differentiating the hot or cold areas in an allocated

storage or shipping unit for Brigatinib China. The most vulnerable areas are located near doors and air vents. It

is important to know the temperature dynamics inside a warehouse or freezer so

that proper measures can be implemented in order to make sure that all products

are stored at the right temperature.

For

the development of temperature-controlled shippers advanced cold chain

solutions are continuously being developed and introduced so that they are able

to cater to the growing bio pharmaceutical market. During the process of

distribution, exporting, and importing, delays and disasters can often be

encountered; which includes the fact that there can be people involved in the

process who don't have the proper knowledge and understanding of the delicate

nature of the shipment.

You cannot deny the fact that in the pharmaceutical business in-transit troubles, changes in the temperature, careless handlers, intense natural weather conditions, and some other forms of shipping problems are frequent concerns. You can buy Brigatinib Intermediate online. Follow us on Twitter