Biotechnology

is the science which combines biology with technology that in pharmaceutical

sector is being used rampantly. This science especially in manufacturing of

vaccinations and genetic testing has proved to be a boon.

Genetic

testing: Genetic testing

has become a reality through biotechnology. Because of such testing it has

become possible for medical science in unlocking many mysteries of the human

body. For example, we can use, genetic testing for determining the sex of to be

born child, spotting early symptoms of cancer in individuals, forensic tests,

and detecting other possible deficiencies that otherwise are hard to detect.

In

the market currently a biotechnology company that deals in such kinds of

testing has great demand and their growth prospectuses too are bright. There

has been enormous amount of manpower and finances spent on the research and

development of genetic testing and the end results with which they arrive up take

the medical sciences to an altogether different level.

In

early 90s worldwide there has been evolution of biotechnology and within a span

of almost 2 decades this science has changed the way a pharmaceutical company functions.

In Bio-tech there is use of molecule products and concepts which comes as a prerequisite

of pharma manufacturing companies.

In

bio-tech based products there are cheaper production costs and this becomes a major

reason why the pharma industry has embraced this technology and has made it an

indispensable part of its own self. Additionally pharmaceutical sector is

service oriented where prime importance is the safety of the end users. Mishaps

can happen due to the minutest of errors in a formulation which later cannot be

corrected. Biotechnology is quite reliable, safe and result oriented which is

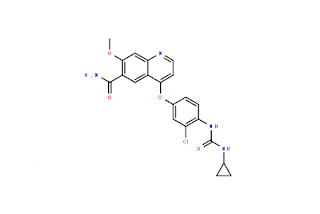

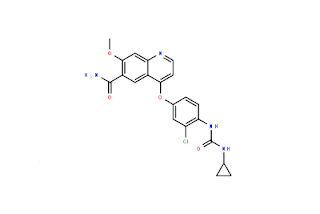

why it was thoughtfully adopted by Brigatinib Intermediate manufacturer across

the globe.

For every industry dynamism and flexibility is essential. The only way a business can survive is by adopting new technologies and upgrading the old ones. In the approach towards new developments and technologies pharmaceutical industry has always been aggressive and biotechnology in every sense falls in the same category. By both pharmacy and biotechnology path breaking solutions have been created and the there is a lot more in future.

Follow us on Twitter

![5-(4-Phenoxyphenyl)-7H-Pyrrolo[2,3-D]PyriMidin-4-YlaMine Intermediate Supplier China](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhFOc8oJEoM1fWnj6Xu9lkpZDtmzsrYChnTvlLLidJCynmyTXuzDGuqxjtfVWaac7FzP9uLeswnxxRP3ZIMm55jaHd5lXH3GoxrMqKN3RXrekBgABbs0UiXBtWS8YqBjO4ABqYxbKvGFf2jzSskD0BCylKWnEtAH7f-N2BUZUZC_kkhda3WLrS1WmVE/w320-h237/5-(4-Phenoxyphenyl)-7H-Pyrrolo%5B2,3-D%5DPyriMidin-4-YlaMine.jpg)

-N4-(3-Chloro-4-Fluorophenyl)-7-((Tetrahydrofuran-3-Yl)Oxy)Quinazoline-4,6-Diamine.jpg)