The continuous flow method is a concrete indispensable process and to generate a chemical reaction it is an effective tool used by API Manufacturer where the reaction is carried out by mixing the reagents. Then, for further completion of the reaction process this liquid or solution is allowed to go through an observation tube. Thus in solution the continuous-flow method also helps to monitor the kinetics of chemical reactions.

The continuous flow synthesis even allows combinatorial synthesis and space integration of reactions, which makes it the most innovative synthetic and pharmaceutical research tool. Using a single flow reactor and flow switch various compounds can be synthesized sequentially. For commercially synthetic processes and preparative standards the routes are designed than the normal batches to expand the synthetic proficiencies.

For the scale-up process, API Manufacturer Company China or synthesis in a lab is sometimes difficult as it make use of reaction equipment that owes to their size and performance criteria. Hence in such cases the process optimization of the scale-up reaction is always a challenge and it considers the monitoring of the reaction parameters, which emphasizes that using continuous flow reactors will help you in understanding and maintaining the process requirements for the optimization techniques.

In a continuous flowing stream continuous flow reactors are devices that carry out synthetic transformations. According to the need and characteristics of the reaction they can be designed and customized. Hence for carrying out the respective flow synthetic reaction customized flow reactors are available.

The continuous flow method provides comprehensive and additional insights into managing the flow chemistry pattern and the transformational process that even makes the method a potentially competent and technically powerful tool.

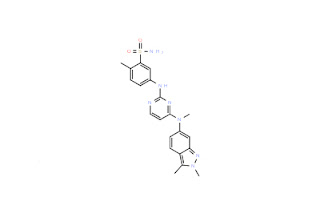

To optimize and standardize the process that is involved the active pharmaceutical ingredient manufacturing has been developed in a modified and innovative way. For many APIs flow synthesis of high- volume pharmaceuticals is conducted using a micro reactor. A continuous flow synthesis process is basically carried out by API Supplier China where each step is optimized and standardized by taking the quality reagents for the reaction so that you can avoid any downstream difficulties and troubles. At the end of the process of sequence final purification is carried out.

Follow us on Facebook

No comments:

Post a Comment